General Purpose Wire Ropes

6x19 & 6x37 Classification Wire Rope (Bright)

6x19 & 6x37 Classification Wire Rope (Galvanized)

19x7 Classification Wire Rope (Rotation Resistant)

6x19 Stainless Steel Wire Rope (Type 304)

6x37 Stainless Steel Wire Rope (Type 304)

7x7x7 & 7x7x19 Cable-Laid Wire Rope (Galvanized - Preformed)

7x7 Galvanized Wire Rope (Aircraft Cable)

7x19 Galvanized Wire Rope (Aircraft Cable)

7x7 Stainless Steel Wire Rope (Type 304 - Aircraft Cable)

7x19 Stainless Steel Wire Rope (Type 304 - Aircraft Cable)

7x7 & 7x19 Clear Vinyl Coated Galvanized Cable (Aircraft Cable)

7x7 & 7x19 Clear Vinyl Coated Stainless Cable (Type 304 - Aircraft Cable)

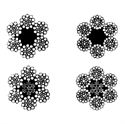

General Purpose Wire Steel Wire Rope is offered in 5 main classifications by Horizon Cable Service. Each wire rope class has their own distinct advantages based on the application in which the wire rope will be used. Typical applications include oilfield, heavy haul trucking, forestry, construction, wind energy and industrial to name a few. Reference the information listed below as a guide on which wire rope is best suited to your application, and feel free to contact us at any time to discuss any concerns on selecting to proper wire rope.

6 x 19 Classification of wire rope includes standard 6 strand, round strand ropes with 16 through 26 wire per strand. This is a good wire rope to withstand abrasion or crushing on the drum, but fatigue resistance is decreased. Wire ropes with independent wire rope cores (IWRC) in general, are more crush resistant than fiber core (FC) wire ropes. This class of wire rope is a good choice where abrasive wear is accompanied by moderate bending. Horizon Cable Service offers this classification of steel wire ropes in bright, galvanized or stainless in sizes ranging from 1/4" – 2” diameters with larger sizes available upon request.

6 x 37 Classification of wire ropes includes standard 6 strand, round strand ropes with 27 through 49 wires per strand. The 6 x 37 wire ropes are important for their fatigue resistance. This fatigue resistance is made possible by the greater number of small wires per strand. Although there are exceptions for special applications, the constructions in the 6x 37 classification are primarily designed to be the most efficient for each wire rope diameter. As the wire rope size increase, for instance, a large number of wires can be used to achieve required fatigue resistance, and still those wires will be large enough to offer adequate resistance to abrasion. This construction of steel wire rope was designed to provide fatigue resistance without having wires that are too small. The greater numbers of wire in the 6 x 37 classification makes these wire ropes more susceptible to crushing. This can be minimized, however, by specifying an independent wire rope core (IWRC) and by using well designed sheaves, grooved drums and proper operating techniques. Horizon Cable offers this class of steel wire rope in bright, galvanized or stainless in sizes ranging from 1/4" – 2” with larger sizes available upon request.

7 x 19 Classification Aircraft Cable is a common industry term for small diameter, corrosion resistant, zinc-coated wire rope originally designed for aeronautical applications. Aircraft cable is a flexible and inexpensive wire rope used in commercial, industrial, construction and marine applications. Also available with flexible, vinyl P.V.C. coating to extend the wire ropes lift by protecting wires from abrasion, dirt, grit or moisture, sealing in lubrication and reducing wear on sheaves and pulleys. Horizon Cable Service offers aircraft cable in galvanized or stainless in sizes ranging from 1/16” – 3/8”.

19 x 7 Rotation Resistant wire ropes are used in applications where a single hoist rope is used to lift a free load or where rotation resistant properties are essential for wire rope performance, a 19 x 7 steel wire rope can be used. The rotation resistant characteristic of 19 x 7 rotation resistant wire rope is achieved by laying 6 strands around a core strand in one directions and the n laying 12 strands around the first operation in the opposite direction. This, when the rope is in tension, opposing rotational forces are created between the inner and outer layers. 19 x 7 Rotation Resistant wire ropes require special handling, selection and usage considerations due to their construction. This classification of wire rope has a relatively low reserve strength thus resulting in a short service life. Horizon Cable offers this classification of steel wire rope in sizes ranging from 1/4" – 1” in bright finishes.